Belt Wipe™

Conveyor Belt Cleaning & Dust Control Optimization Device

75% more effective than traditional conveyor belt cleaning solutions.

Dust

Belt Wipe™

Features & Benefits

Conveyor Belt Cleaning & Dust Control System

The highest-rated cleaning effectiveness in the industry of 92%~96%; while competing technologies are 20%~30% effective.

- Urethane cleanerheads are conformal to irregular belt surfaces and deflect away from splices

- Typically installs in 1/2 day for two millwrights, for common belt widths

- Highly durable, simple, no rotating parts, no electricity or controls/automation required

- Connects easily to existing dust collection aspiration piping, or a local suction system can be utilized

- Eliminates belt turnovers and expensive rotary belt cleaners

- Manufactured in SSAB Hardox® 500 TUF for mining, or with ATEX™ urethane for combustible dust

- Smooth and cleated belt compatible

- Cleans entire beltline and eliminates buildup on rotating conveyor components

- Ultra-low aspiration volume versus rotary cleaners

Suitable for a wide range of industrial applications.

Designed to remove dust, particulate, sticky & dry materials from smooth, cleated, and irregular conveyor belts.

Aggregate, Agricultural, Cement, Coke, Forestry, Frac Sand, Mining, & More

Clean Your Belts!

Make your conveyor belts shiny again! Industry leading cleaning effectiveness of 92.5%, and in some applications as high as 95%+

image:

Grain terminal conveyor belt, transporting durum – note the shiny belt surface after Belt Wipe cleaning

Eliminate up to 95% of carryback dust.

Is it snowing below your conveyor belts? The Belt Wipe can eliminate up to 95% of carryback dust, virtually eliminate “snowing” below rotating components, and clean up the entire beltline

Simple installation & maintenance.

Typical installations are ½ day for two personnel and a maintenance walk-by is required every 4 months.

The Belt Wipe eliminates costly belt turnovers and rotary belt cleaners; replaces ineffective air knives

Quality you can trust.

Durable construction, simple and effective top-quality components, field-proven in multiple industries since 2017, Made in Canada

96% effective

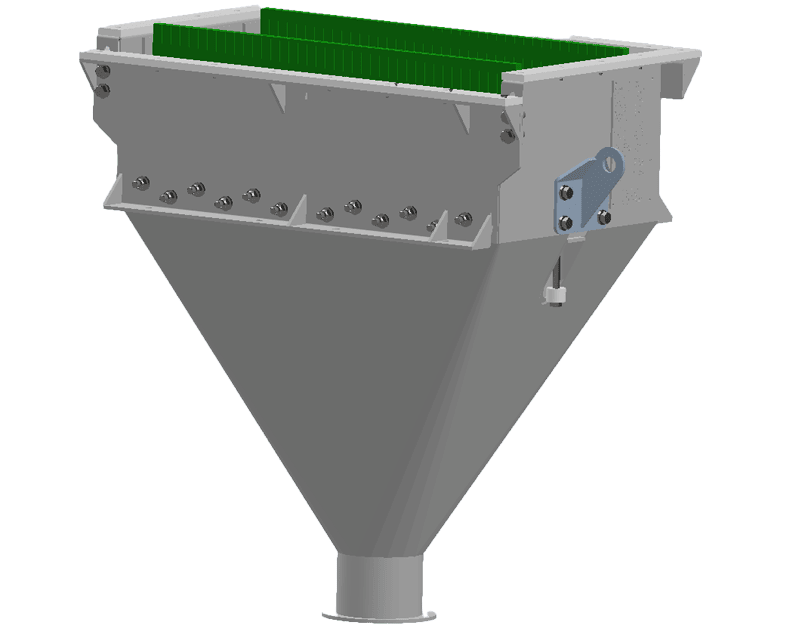

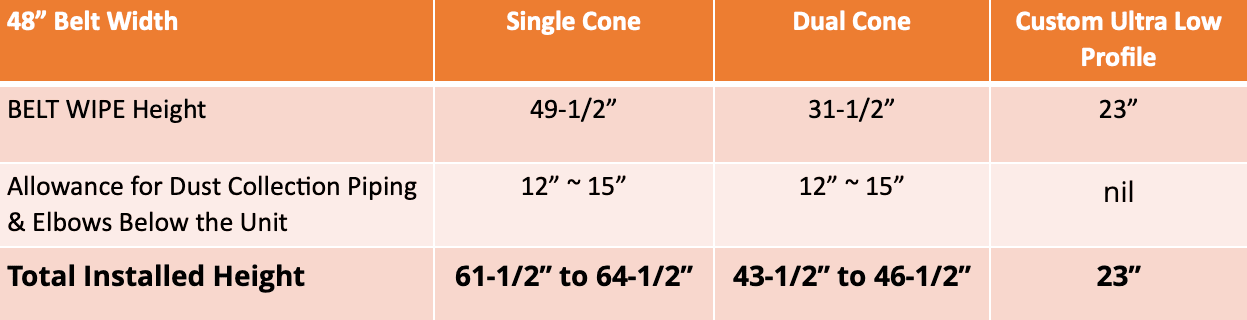

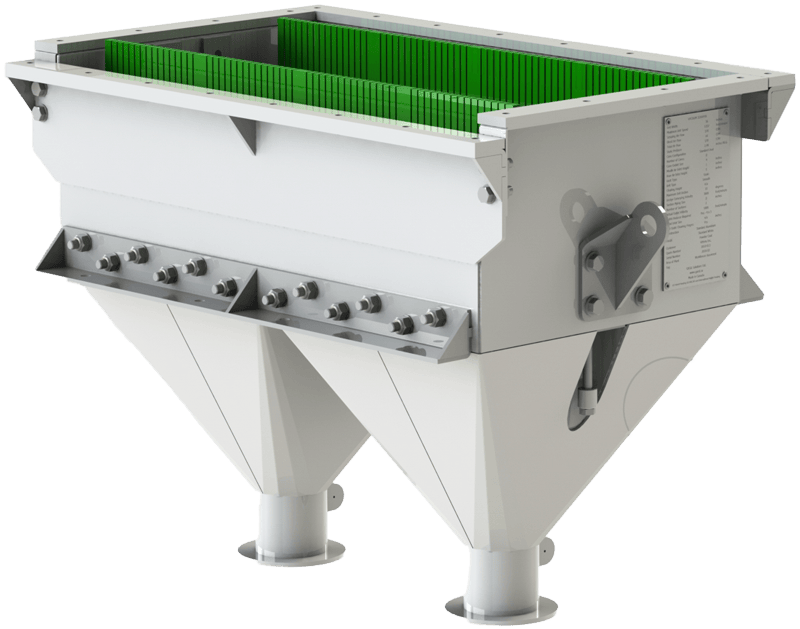

The Belt Wipe™ is Available in Three Versions

Sizing & Adaptability

An example is shown below of the overall dimensions of the three different versions of the Belt Wipe to demonstrate the product’s adaptability to site conditions. Please get in touch with us to configure a preliminary product selection that our sales and engineering team will customize and finalize for your application.

Before You Order

Note that the Single-Cone and Dual-Cone Belt Wipes are a standard order item that can be manufactured for non-combustible nuisance dust applications and can be manufactured in combustible dust versions with ATEX™ certified urethane – all three versions of the Belt Wipe can be manufactured both in an aluminum body construction for non-abrasive dust applications and in wear resistant plate for abrasive dusts, as well as many other options depending on end-user requirements.

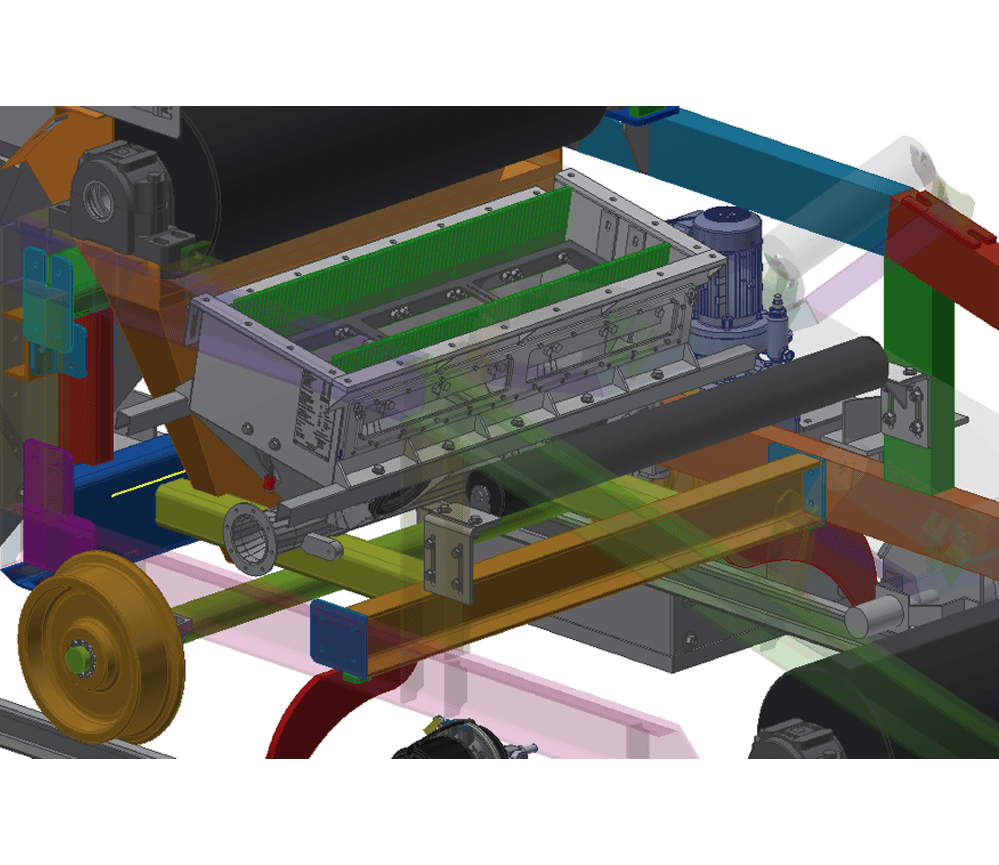

The Custom Ultra Low-Profile Belt Wipe is a made-to-measure product that can be fitted into limited space applications such as:

- Tripper Heads & Shuttles

- Floor-Mounted Conveyors

- Conveyor heads with limited space due to nearby equipment and structural supports

If the Single-Cone or Dual-Cone Belt Wipe do not fit your application’s space constraints, please contact us to initiate discussions for potential fitment of a Custom Ultra Low Profile Belt Wipe, and include the following information when you contact us:

- Belt width, speed, smooth or cleated, belt incline

- Dust type, abrasive or non-abrasive, combustible or non-combustible, angle of repose for the fugitive dust

- Pneumatic conveying velocity for the dust

- Photos and scale drawings of the potential fitment location

- Maximum height available for installation

- A link to where the files, photos and drawings of the potential fitment are stored

Alternately, if your company or IT environment blocks the sharing of files and folders and the files are too large to email, we can provide a file transfer link or SharePoint site link to facilitate the transfer of large files – please contact us for assistance.

Self-Install Kits

A complete pre-engineered conveyor belt carryback dust control kit of self-install components can be supplied, consisting of:

- The Belt Wipe (mounted on the underside of the conveyor’s head end)

- Dust Collection Piping, with supplied piping & fittings material to match the customer’s application and dust type

- Small Modular/Local Dust Collector & Filter Unit

Larger kits can be supplied that include enough piping, fittings and couplings, and a large enough dust collector for complete conveyor head-end dust control. Enhanced/comprehensive kits are available for head-end dust control plus dust control at the tail end of the receiving conveyor, including hood design, wetting nozzle design & placement, etc.

For space-limited applications, screw conveyors and chain conveyors can be supplied to move the collected dust cake from the dust collector’s bottom outlet onto a receiving conveyor. Blowpipes and air pumps are another option to convey the collected dust cake from a primary dust collector/filter to a receiving dust collector location.

Please Contact Us to discuss the available self-install kit options.